Energy and Vertical Farms

Vertical farming is hot.

The idea that we should grow food under highly-controlled conditions in urban high-rises is getting plenty of media attention, along with pleas for public and private investment. A new vertical farming book by retired Columbia professor Dickson Despommier came out in October, and Sting bought the movie rights.

Vertical farm promoters claim these buildings will solve every problem from farmland shortages to population growth. They seem particularly fond of futuristic renderings of glassy skyscrapers alive with plants bathed in electric light. The grow lights are necessary because most crops would fail under the meager ration of sunlight that could filter into the depths of a skyscraper.

Proponents of vertical farming commonly say it will save energy by eliminating the need for tractors, plows, and shipping. Some even think that vertical farms can incorporate enough solar panels, wind turbines, and methane generators to be net energy producers. For the most part, vertical farms are more vision than reality, but a few real-life examples are appearing, offering opportunities for critical evaluation of proponents’ claims. In this post I examine one such example from a farm energy perspective.

Vertical farming: A real-life example

An article in the Milwaukee Journal-Sentinal caught my attention last July because it describes an actual aquaponics operation in Racine, Wisconsin, growing fish (tilapia) and lettuce in a former industrial warehouse.

An old JI Case building once used to manufacture plows for farm fields is being transformed into a dirtless vertical farm where fish and lettuce are grown in a symbiotic system.

The farm, in a part of the city that once was an industrial hub, potentially could produce the same amount of food as 40 acres of land without the use of pesticides or fertilizer…

Fish are fed in a warehouse in Wisconsin. Waste water provides a nutrient solution for lettuce produced under grow lights.

The article offers some numbers to consider:

- 10,000 square feet of warehouse space are currently used for production;

- 7,000 heads of Bibb lettuce are harvested monthly;

- a pound of tilapia is harvested for every four heads of lettuce;

- the monthly electric bill is $2,800;

- the farmers plan to expand to fill the 200,000 square foot warehouse.

Two-thirds of Wisconsin's electricity comes from burning coal (source: Union of Concerned Scientists. Click image for original report).

Photosynthesis is fueled by grow lights, since sunlight never reaches the lettuce. The lights run at night, when electric rates are as low as 5 cents per kilowatt-hour. At this rate, the farm is using about 56,000 kilowatt-hours of electricity each month (calculation). Most of Wisconsin’s electricity comes from burning coal mined out of state, at a conversion rate of about 2 megawatt hours per ton of coal. Therefore, providing electricity to this model vertical farm for a year requires the equivalent of 336 tons of coal (calculation) (220 tons of actual coal, plus nuclear, natural gas, hydro, and other electricity sources). If the operation expands to 20 times its current size it will eat up 6,700 tons of coal equivalent annually.

Then there’s the energy that goes into producing the feed. A lifecycle analysis of intensive tilapia production by Nathan Pelletier and Peter Tyedmers, at Dalhousie University, found that production of feed requires about 9 gigajoules per metric tonne, or 15 gigajoules per tonne of fish. That comes to 143 gigajoules of energy (calculation) — equivalent to another 6 tons of coal (calculation assumes 27 GJ/t) — for enough feed to keep this little vertical farm going for a year. If the planned expansion is completed then producing feed for the facility will demand about 116 tons of coal equivalent annually. Feed production accounts for 91% of energy use in intensive lake-based aquaculture, but that same energy investment amounts to less than 2% of the energy used to keep the warehouse-based farm running (calculation).

A platter heaped with eight pounds of coal demonstrates the quantity needed to generate enough electricity to grow a head of lettuce and a quarter pound of tilapia in a model vertical farm.

The newspaper article doesn’t mention how much energy it takes to heat and cool the warehouse. Tilapia grow best at temperatures between 72 and 90ºF, and lettuce grows best between 60 and 65ºF. Both the fish and the lettuce could grow at about 70ºF, but the lettuce will start to bolt at higher temperatures and tilapia growth will slow at lower temperatures. If the fish and the lettuce are in the same section of the warehouse then the temperature must be maintained within a very narrow range, which takes energy. Heating and cooling account for the bulk of energy use in temperate region greenhouses, but probably require less energy in a warehouse filled with large pools of water.

Lumps of coal will be used to fuel the furnace of a small tomato greenhouse in Kentucky. Heating and cooling account for most of the energy used by most greenhouses.

By my calculations, producing a head of lettuce and a quarter pound of fish in this model vertical farm uses the energy equivalent of more than eight pounds of coal (calculation).

Worse than greenhouses

Back in 2000, Swedish researchers Annika Karlsson-Kanyama and Mireille Faist calculated the amount of energy used to get lettuce to the plate in Sweden’s industrial food system. They found that greenhouse-grown lettuce took more than 100 times as much energy to produce as field-grown lettuce (original report; see Tables 7 & 8). Storing and transporting lettuce took about the same amount of energy regardless of production method. For the field grown lettuce, storage and transportation accounted for two-thirds of the total energy needed to get lettuce to the plate. For the greenhouse-grown lettuce, storage and transportation accounted for just 2% of that energy investment.

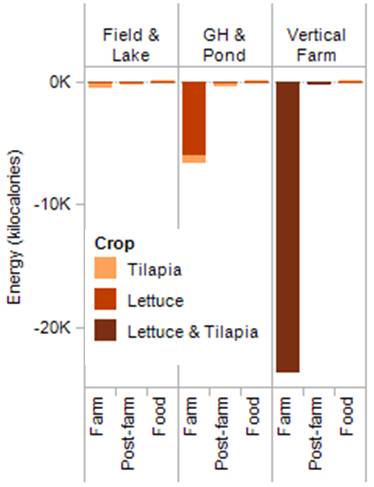

Energy expenditure and return for a head of Bibb lettuce and a quarter pound of tilapia from three production systems. Systems compared are low input field and lake production, high input greenhouse and pond production, and an integrated vertical farm system using electric light. Expenditure (negative) is associated with the production (farm) and processing/distribution (post-farm). phases. Return (positive) is the metabolic energy derived from consuming the food. Click chart for enlarged interactive version.

Delivered to the plate, the field and greenhouse-grown heads took about 125 and 6,000 Calories, respectively. Eating the lettuce itself provides just 21 Calories of metabolic energy. If we are concerned about energy use in our food system, concluded the Swedish researchers, we should stop growing lettuce in greenhouses.

A food factory like the profiled vertical farm makes greenhouses look good. At more than 24,000 Calories for a head of lettuce and a quarter pound of tilapia (calculation), it consumes 3.5 times more energy than a greenhouse and pond, or 33 times more than a field and lake.

Replacing coal with switchgrass

Far from saving farmland, a food system that incorporates vertical farms fueled by farm-grown renewables could dramatically increase demand for farmland.

An acre of switchgrass typically yields about six dry tons, shown here as a trailer load of round bales. This load could power a typical American home for 5 months but would be used up by 10,000 square feet of a model vertical farm operation in under 5 days.

Switchgrass, for example, has been proposed as a coal replacement for electricity generation. A ton of dry switchgrass contains about two-thirds as much energy as a ton of coal. Switchgrass typically yields about 6 tons per acre, so 84 acres could produce the 500 tons of switchgrass needed to generate enough electricity to keep the profiled farm going for a year at its current scale (calculation), and 1,770 acres would be needed to keep it going after the planned expansion. Add the 84 acres of switchgrass to the 10,000 square feet of warehouse space currently used, and the annual lettuce yield plummets from 366,000 (calculation) to 1,000 heads per acre (calculation). A typical California lettuce farm collects 50,000 heads per acre over two annual harvests.

Replacing coal with wind

Two wind turbines generate electricity for the Spirit Lake School District in Iowa. The first began operation in 1993 and has a 250 kilowatt capacity; the second has operated since 2001 and has a 750 kilowatt capacity. Each turbine cost about a dollar per watt of generating capacity to install, and generates less than a quarter of its rated capacity. If conditions are similar in Racine, the smaller turbine would satisfy half the farm's electricity demand, and the larger turbine would satisfy twice the farm's electricity demand.

Wind is probably a better renewable energy source than switchgrass near the shore of Lake Michigan, where the farm is located. Indeed, vertical farm renderings often feature wind turbines.

Hundreds of wind turbines have been erected across Wisconsin, with many more planned. Each typically contributes about a quarter of its rated generating capacity to the grid, due to the intermittent nature of wind. For example, a $780,000 wind turbine erected by Iowa’s Spirit Lake School district in 2001 has a generating capacity of 750 kilowatts, but has actually generated an average of 173 kilowatts since construction. Assuming similar winds in Racine, an identical turbine would generate more than twice as much electricity as is currently used by the model vertical farm (calculation). Another eight of them would be needed after the planned expansion, more than doubling the expansion’s $6 million price tag (calculation).

Of course nine wind turbines this big wouldn’t fit on the warehouse site, and Wisconsin’s emerging rules on wind siting will likely require a 2,500 foot setback between turbines and property lines, prohibiting construction of even one turbine in an urban environment. Wisconsin has an active anti-wind lobby which is raising concerns about safety, noise, bat kills, and other perceived drawbacks associated with wind turbines in close proximity to people.

Replacing coal with methane from waste

Gordon Graff's Skyfarm concept for downtown Toronto would recycle organic waste into methane gas to generate electricity.

The energy demanded by artificial lighting of vertical farms concerns Gordon Graff, a Toronto-based architecture student who designed a vertical farm concept called the Skyfarm. He estimates that his proposed 59 storey farm could grow enough produce for 50,000 households, but lighting it would require 82 million kilowatt hours each year — as much electricity as is typically used by 8,000 North American households. Graff proposes that half of this energy could be recovered by burning methane generated from the farm’s own waste. Based on the kilogram per kilowatt hour conversion rate calculated by the University of Reading’s Charles Banks, the Skyfarm would have to produce 45,000 tons of wet waste annually to satisfy half its energy demand through waste recycling (calculation). The remainder could come from methane generated from other municipal wastes.

Building biogas digesters to make electricity from municipal waste is a good idea, but using that electricity for grow lights to replace sunlight probably isn’t. If Toronto were to build the biogas digester that Graff envisions for his Skyfarm, but leave the rest of the project on the drawing board, the city would have 90,000 tons less waste for its landfills every year, and 8,000 fewer homes to power with coal and nuclear energy. If the rest of the Skyfarm is built, the city would have to resume landfilling 45,000 tons of waste and return those 8,000 homes to coal and nuclear energy.

Replacing coal with solar

Vertical farm renderings often feature opaque roofs covered with solar collectors. Solar dish collectors can convert about 30% of the energy they receive from sunlight into electricity. High pressure sodium lamps — the most efficient grow lights available — convert 12-22% of that electricity back to light. Therefore, a good solar system used to power electric lights produces less than 7% as much light as it collects (calculation). This contrasts with a clear glass roof, which transmits 90% of incoming solar radiation to the plants below. Spread over 10 storeys, a rooftop solar collector used to power artificial lights would do well to provide 0.7% as much light as would be available to a plant growing on the roof. A rooftop solar collector is an expensive and ineffective substitute for a glass roof.

Not organic

Vertical farms are often described as organic because they do not use pesticides. Organic farmers are quick to point out that organic agriculture involves much more than simply avoiding synthetic pesticide use: The term refers to farming systems that build soil organic matter to feed the diverse array of beneficial soil organisms that interact with plant roots. According to the USDA, organic farms respond to “site-specific conditions by integrating cultural, biological, and mechanical practices that foster cycling of resources, promote ecological balance, and conserve biodiversity.” In contrast, vertical farms wall themselves off from nature and attempt to replace free ecosystem services with energy-intensive engineering.

Whether soil-less production systems can even qualify as organic is controversial. This April, members of the National Organic Standards Board voted 12-1 to recommend that the following clarification be adopted by the USDA:

Observing the framework of organic farming based on its foundation of sound management of soil biology and ecology, it becomes clear that systems of crop production that eliminate soil from the system, such as hydroponics or aeroponics, cannot be considered as examples of acceptable organic farming practices.

This language will likely be adopted as part of a new standard for organic greenhouse production, outlawing use of the word “organic” in the USA to describe terrestrial plants grown hydroponically.

Organic aquaculture standards are also mired in controversy. The National Organic Standards Board has recommended that synthetic amino acids and protein from wild aquatic animals be prohibited in organic feed. If enacted, these rules could increase the energy used to produce organic feed. Adoption of organic aquaculture standards is favored by groups like The Environmental Defense Fund and the Ocean Conservancy, but opposed by the likes of Greenpeace and the Sierra Club.

Organic certification of a system like the profiled aquaponics operation would require approval of separate organic farm plans for the tilapia and lettuce components of the farm. At present, neither would be approved. There might be hope for the tilapia component, but it doesn’t look good for the lettuce.

Local, not sustainable

The energy required to grow plants under artificial light far exceeds the energy required to transport food from fields fueled by sunlight. A recent analysis of the US food system by a team of USDA economists led by Patrick Canning found that transportation is the smallest segment of the food system’s substantial energy demand. In general, growing food uses more than three times as much energy as transporting it. Vertical farms dramatically expand the agriculture slice of the food energy pie in order to reduce the much smaller transportation slice. They do not reduce the amount of energy used to process, package, sell, store and prepare food, which accounts for more than 80% of food system energy use.

Energy used by components of the US food system in 2002 (right), relative to total US energy use (left). Data from Canning et al., 2010 (Click image for report).

Dreams dashed by thermodynamics

Despommier’s book on vertical farming brims with idealism, but is frustratingly short on details. His Columbia faculty colleague, Vincent Racaniello, describes it as a “dream by a particularly good dreamer.” Given Despommier’s admission that he has neither the architecture nor engineering skills to work out the details himself, Racaniello calls for more rigorous analysis from those with appropriate skills.

In her forward to the book, Majora Carter anticipates that future vertical farms will be very different from those in Despommier’s dreams:

In the time between now and the realization of Dickson Despommier’s vision for our food system, there are many opportunities for innovation and entrepreneurship. If the skyscraper farm is like a 747 jetliner, we are now at the stage of the Wright Brothers. […] There will be many failures as a legion of tinkerers and engineers all struggle to take off […]

While it’s possible that Despommier’s visions of vertical farms are akin to the Wright brothers’ early visions of flight, I suspect they’re more like alchemists’ dreams of turning lead into gold. Alchemists didn’t fail for lack of tinkering and engineering. They didn’t even fail because their task was impossible. Today’s physicists can change lead to gold by removing three protons from its nucleus, but doing so requires a vast energy input that is far more costly than the value of the gold produced. Like alchemy, growing food in skyscrapers is technically feasible, but isn’t worth the energy cost.

Trackbacks

- Vertical Farming explained

- What is Vertical Farming? - Save the Earth

- Vertikalna poljoprivreda: Budućnost ili znanstvena fantastika? - POTICAJI.INFO -POTICAJI.INFO -

- swordofscience | Emerald Cities – Vertical Farming

- Vertical Farming Part 2: Pumpkins in the Sky « Nature @ WSU

- Energy and Vertical Farms | DesignTreat

Michael, you did a great job, here.

Tho’, as we can all clearly see, some people’s urbo-centric educational bias prevents them from objectively evaluating this concept.

You are right, there is no economically viable substitute for free sunlight!

In 58 years of working, daily, with the laws of physics, on farms, over half of this planet, I have seen technologies stabilize and enhance natural processes, but never out-perform them or overcome any law of physics.

I guess that is why they call them laws.

“Vertical Farming” is a spectacular idea, but is not new, and has no inherent connection to any type of building or to artificial light.

The Native Americans practiced a polycultural form of vertical farming, which was highly efficient and productive. They planted four symbiotic crops (the well-known annual Three Sisters, and a perennial Fourth Sister) in the same tilled area, first and foremost, Sunroot, Helianthus tuberosus, a very tall, full season perennial forage and root crop, whose tubers were dug in the Spring, thus tilling the soil, for the planting of Corn, Zea mays, a tall, mid to late season, grain and forage grass, accompanied by several climbing legumes (beans/peas) of early, mid and full seasons, and several understory cucurbitae (squashes) of early, mid and late seasons.

This system of four levels of solar collection and four harvest seasons provided exceptional advantages of high energy efficiency, abundant production, continuous harvest and ultimate sustainability.

This and every other energy efficient form of vertical farming will be imperative for our need to feed more people on less land, in the future.

More reliable sources prove other energy consumption than presented here. Furthermore, the production costs of pesticides, Herbicides and other chemicals are completely ignored.

Your calculations are still wrong. Irrigation and Water doesn’t take place in your measures. Costs for restoring environmental damage polution etc, doesn’t take place in your calculation? For a proper evaluation, it has to! Therefore I suggest, do some study.

Someone told me once: don’t lie, unless you could believe it yourself!

BTW, Annika and Merreil these two swedish blond girls, must take some math lessons two. Things have changed from 2000 to now.

You also left out the amount of water that is wasted with traditional farming and the amount land that is wasted as well. I saw you mentioned in a few comments above that traditional farming actually helps with the water cycle?! I couldn’t disagree anymore with you, and I think hydrologist would disagree as well. It does nothing but take water from the aquifer and then puts back polluted water with pesticides and all the chemicals that go along with it. If land based cropping systems really recycle the then why are they not doing currently? Most of these farmers essentially flood there whole operation with no care in the world for how much water is used, and then they have the nerve to complain about the drought. Overall I would say there are way more negatives with traditional farming then with vertical farming. Your argument is one aspect of farming and your ignoring all of the other aspects that vertical farming does better, let alone it would be much healthier food. Also I would like to add that your calculations for KWH used to light the interior of the structure would be with using old school incondescent bulbs, with new technology and high efficient LED’s your calculation would be much smaller.

This is an interesting article, but when you talk about traditional farming you completely ignored all of the problems it causes. In fact you tried to turn those into positives. It may cost more energy to establish a vertical farming structure, but in your energy calculations you are obviously not including fossil fuel usage by traditional farming, thus skewing the numbers. Also traditional farming is completely outdated and pollutes water heavily along with destroying ecosystems and taking up large amounts of land mass (which you also failed to mention.) As far as you picking on the organic factor of vertical farming I would consider something grown locally and fresh WAY more organic then what traditional farming provides, which has a ton of pesticides and herbicides all over it and even has added perservatives to keep it “fresh” during its long trip. Can you please explain to me how you think traditional farming is more organic? In addition you are correct that there is more development needed but that does not make it less of a solution to the current agricultural problems we face (which you didn’t mention.) Have you considered the possibility of using wind, solar, and methane gas all at the same time to power the structure? How great would it be if we could stop putting waste in a landfill and actually start making food with our waste? Its all possible it just needs a lot of work. I feel like you are coming at this with a complete pessimistic view, which is understandable, but you are ignoring the very very large issues of current farming and I think vertical farming is a better solution, it once again, like everything else that is created, needs more development. On another note vertical farming will have a hard time getting political support because of articles like this and the fact that there are corporations who benefit greatly from current farming methods, at the end of the day it is obvious that we need to change.

Diversity fosters dialogue and helps to make important issues more visible and engaging. It takes time for ideas to be evaluated, tested and to evolve. Our planet has both grasslands and boreal forests. Cites will continue growing and pushing up and are not going away any time soon. When we are up against large entrenched fossil fuel economies and thinking let’s not prematurely shut down new lines of thought before they have been properly explored, tested and given a chance to evolve and especially if they help attract new minds to consider the important issues at had.

Down in dis missisipiay we dont take no rich boys wit dem fine hats bringin dat techy crap in dem homeland. FARMING IZ DA WAY OF LIFE, WE DOONT WANT DAT FUTURE DIRT.

Dem bitchz Donnt no nuttin bout reel farming, we don in wisconsin work hard fo food.

The article is well-written and well-argued, but I disagree with the conclusions. There is a revolution in energy-efficient lighting and solar technology. At current rates of improvement, a watt of sollar energy will cost half as much as a watt of coal energy by 2028. LED lighting improvements are also quite rapid. The combination of these two developments should make vertical farming practical in some regions sometime in the next 20 years. Just as the high upfront cost was a barrier in first and second generation computer and as solar was ten years ago, naturally vertical farming will be expensive while tinkering with the technology. Even if it’s not practical as a universal farming solution it may be quite useful in arid regions in long-term drought conditions where cost is not the primary concern.

The farm in your example is also not growing vertically. we are not just trying to eliminate the transportation energy using vertical farming. It is eliminating distribution cost/energy which is the goal. Transportation cost/energy is only a small slice of overall distribution energy which is the majority of the cost of a good.

Hi Alex,

I am interested in connecting and learning more about your farm in action. I am looking to find funding for such a venture in Hong Kong and hope to learn from you if you are happy to share.

all the best

Darren

We are using 10,000 kWh per month to produce the same amount of fish and heads of lettuce as in the example farm but we are not growing lettuce. We are growing a variety of herbs right now. We are also only using 1500 sq ft of floor space. We are currently using HID lights and when we switch to LED we will be able to reduce that number to about 4000-5000 kWh for the same amount. Then possibly by rotating our towers being able to take out 2-3 lights and replace them with a low wattage motor to reduce electricity use even further. We will also be working on eliminating the use of pumps through a combination of siphons, high lifter pumps, hydraulic ram pumps, and gravity, further reducing our electric use.

You are also incorrect about the vertical farms not reducing the amount of energy used to process, package, sell, store and prepare food. By not having to truck food that distance, it does not have to be processed, packaged, and have preservatives added to be stored for the long haul and have such a long shelf life to meet those requirements. It being local and fresh and being able to be supplied fresh on a constant basis by staggering planting times and being able to grow 24/7/365 eliminates some of the packaging and storing requirements. Anything that goes bad or isn’t up to standard is returned to us and put in our compost.

I have contacted and looked at more pictures from the farm in your article and can say they are not nearly as effcient as they could be. For starters they are not using light movers.

And as far as fish feed we will be using Black Soldier Fly larva and duck weed. The larva will eat meat and dairy as well as paper, vegetable waste and so on leaving behind more compost. This eliminates some of the problems in traditional composting and restaurant waste having to separate oils and meat out of the pile. They are also self harvesting. Duck weed doubles its mass every 36-72 hours. This gives our fish 2 food sources while also giving us compost to use in the growing system again. This eliminates the dependence on chemical nutrient hydroponic solutions traditionally used and all of the waste produced in making those nutrient solutions and the pollution from changing reservoir tanks.

Also not to mention putting people back to work in their local communities and rebuilding local economies. What’s that worth?

HPS lights are not the most efficient growing lights available. Ceramic Metal Halide and LED are much more efficient considering they actually put out a spectrum that is usable in photosynthesis.

USDA is not the only organic certification body and standards that exist. OEFFA is another and by actually using and building compost in our system we should be able to become certified.

Other problems in the current food system are GMO crops, soil erosion, water depletion, deforestation, all the health risks associated with corn fed animals and the risks with using fertilizers and pesticides.

I don’t think it will be an end all be all but it has its place. Serious work needs to be done on reforesting corn fields with food forests.

The Wikipedia article on Grow Lights offers a well-referenced table of luminous efficiency ratings (http://en.wikipedia.org/wiki/Grow_light). Neither metal halide nor LED match the efficiency of HPS. It is true that they can put out light that better matches the photosynthetic spectrum, but none of them are able to convert more than 22% of the electrical energy they consume into light. That optimistic 22% figure is the one I used in my calculations.

All 55 organic certification agencies in the USA — including the Ohio Ecological Food and Farm Association (OEFFA) — have to meet federal organic standards determined by the National Organic Program (http://www.ams.usda.gov/AMSv1.0/nop). They are audited routinely by the federal government and can lose their certifier status if they certify products as organic that do not meet the federal standards.

This post is about energy use and vertical farms. Energy use is only one of many issues associated with the current food system. It is important to address concerns related to GMO crops, soil erosion, water depletion, deforestation, health risks, and agricultural pollution, but a ‘solution’ that causes agricultural energy use to skyrocket probably isn’t the best approach.

That wikipedia article isn’t very good and doesn’t tell the whole story.

Lumens don’t mean anything to plants. If lumens (or luminous efficiency) were really any indication of usefulness for plant growth, we’d all be using low pressure sodium. Low Pressure Sodium lamps are virtually useless for growing plants. LPS emits nearly monochromatic light at 590nm, and has a very high luminous efficiency (in fact, it highest luminous efficiency of any gas discharge source currently available).

The other thing to notice about the comparison is that the photopic efficiency of light approaches zero right about where it’s effectiveness for photosynthesis peaks at both the blue and red end of the luminous efficiency curve. So rather than being a good indicator of how useful light is for plant growth, the lumen is just the opposite. Stated another way: for any two lamps having similar radiant efficiency but different luminous efficiency, the one having lower luminous efficiency is almost guaranteed to be more efficient for plant growth. What we are looking for is high radiant output, with a low lumen rating.

Photosynthetically active radiation (PAR), measuring radiance in watts, is much better than photopic units (lumens or lux) or radiometric units (watts or watts/m^2). PAR is a mesaure of lamp output in the spectrum that is actually useful to the plants. However, this data is only available for a small number of lamp models. An additional limitation is that the PAR watt treats all wavelengths between 400 and 700nm equally, but all wavelengths within that range are not equially effective for plant growth. Despite these limitations, PAR efficacy (PAR watts emitted/watts consumed) is a decent indication of efficiency for horticultural lamps. PAR irradiance can be measured using a spectroradiometer.

Irradiance at the plants can be measured directly, as photosynthetic photon flux density (PPFD). This is measured in Einsteins (E), which is not a SI unit. One Einstein is one mole of photons, regardless of wavelength. Irradiance levels on the surface of the earth occur on the scale of micro-Einsteins. PPFD is observed directly using quantum meters that measure microEinsteins per square meter per second, for photons having wavelengths between 400 and 700 nm. This has the same limitation as the PAR watt, by treating all wavelengths in the range as equally useful for plant growth.

We can get a rough idea of the how efficient a lamp will be be for plant growth by looking at it’s Spectral Power Distribution (SPD) and comparing it to the action spectrum of photosynthesis. The more useful lamps produce most of their light around the chlorophyll absorption peaks, and produce less light away from those peaks. However, without knowing either the radiant output (in watts) or PAR output (also in watts), we can’t calculate anything objective, like it’s overall PAR efficiency.

I have replaced a 1000 watt HPS light with a 400 watt LED light panel and get the same growth in roughly the same area.

I don’t see how this isn’t more efficient in terms of energy use to obtain the same yields. Not to mention HPS lights losing spectral output and having to be replaced roughly every 2 years of use if not sooner and an LED lasting up to 50,000 hours of use.

The Ceramic Metal Halides have 5% spectral loss over their whole life time making them usable throughout their full lifetime and not having to replace early like Metal Halide and HPS

Also in addition to this with the remaining property we will be using Permaculture techniques at developing food forests and gardens around the property. Part of the goal is to make use of unused space here.

I’d be willing to bet that the food forests and gardens will be orders of magnitude more energy efficient than the vertical farm.

We will not come close to the output and productivity of the warehouse on yearly basis. Also not taking into account crop failures, diseases, pests, etc. Though with well balanced planting we should be able to buffer against a lot of those things. We will still have polluted run off from the rest of the neighboring farms though which is another advantage of growing indoors. We can filter the air and water.

As far as heating and cooling goes we will be using the Ceramic Metal Halides (Different than metal halide) in the winter and the lights will put off enough heat to bring the growing area up to temp allowing us to double up on light and heat for the same amount of electricity.

For the summer time again we will be experimenting with under ground cool tubes and now also Coolerado’s A/C units. Which was actually just brought up today in a meeting as a potential cooling option.

http://www.coolerado.com/products/

http://www.coolerado.com/video/

More specifically for a 10,000 sq ft warehouse we would use 4 C60 units which consume 710 Watts at peak running but have variable speed fans and usually run around 500 watts. they use no chemical refrigerants.

The other advantage to these is they constantly bring in fresh air eliminating the need for supplemental CO2.

Also switching to LED’s will greatly reduce the heat generated in the rooms for the summer.

This combination gets us a longer life out of our Ceramic metal halides and reduces inputs needed to heat and cool.

We are looking at an output of around 15000 heads of lettuce a month. The amount of fish is unknown as we are currently building and incorporating those systems. We are also testing tomatoes and basil as well. I’d be happy to and will be sharing numbers as we get out of development and into production.

I am the owner of a vertical farm that is in development. We use the Vertigro growing system http://vertigro.com/, and use a combination of coco peat and compost that is made from the food waste from the restaurants we supply to. We also utilize an aquaponic system for nutrients and providing fresh fish. We currently use Ceramic Metal Halide bulbs and LED’s but are talking with a company called Sunlight Direct to use fiber optics to bring sunlight into the growing area, which will greatly reduce the amount of electricity and artificial lighting that is traditionally needed in indoor growing. We have started growing ivy over the whole building to reduce temperature fluctuations and will be working this spring on employing underground cool tubes so that traditional A/C units will not be necessary. This whole industry is still an experiment.

I like the idea of bringing sunlight into the growing area. Fiber optics have great potential to reduce energy use associated with artificial lighting, but you will have to invest an awful lot in fiber optics to realize that potential.

The Vertigro system can be used for outdoor production and in traditional, single story, greenhouses that rely chiefly on sunlight instead of artificial light. That makes more sense to me.

Which we will be doing as well. There is a 1 acre greenhouse and 24 acre property for sale. Once we finish warehouse development we will be looking at purchasing the property or one similar but we don’t think this one is going anywhere. Greenhouses have their own ineffciencies and challenges to overcome as well though. Mainly winter. Keeping fish alive and greenhouse warm enough. We have talked about putting our composting operation inside the greenhouse to heat it in the winter so we don’t have to rely on propane tanks but we will see when we get there.

Hi Alex, I would be very interested in connecting further and learning more about the farm you are building. I am hoping to do something similar in Hong Kong and any thoughts and experience would be very much appreciated. If you are happy to connect please email me at DPC3000 AT googlemail DOT com

cheers

Excelent article and it’s amazing to see the responses from those who stil don’t wan’t to believe that vertical farms don’t work.

I learned about the vertical farm concept from a co-worker who is a farmer and I did some back of the envelope calculations and came to the conclusions you did but this fellow still didn’t want to stop believing.

I think the real solution in the future for food production is to

1. Eat less meat thus using less farmland

2. Use more labor and less mechanical/chemical inputs to create greater yields and less energy use, waste and erosion.

All the above makes little business/profit sense but will preserve our natural capital.

Thanks for acticle,

I was looking on more calculation about vertical farmin and found this.

These calculations are needed to outweight wishful thinking in lines “this must work, because we will be so many in 2050, and there is realy no way we can feed ourselves”.

However I think you jumped over wind option too easy – wind will cost in range of 50usd/kwh (http://en.wikipedia.org/wiki/Wind_power#Economics), it may be optimistic, but quite reasonable expectation. If this industrial farm can make sense with current electricity price I think they can count on wind being available at reasonable cost in future.

Re solar – of course generating electricity from rooftop and then running electric lights within building is most stupid. I think the Despommier’s idea was to build tall glass greenhouse – so 90% of solar is delivered to plants, at least in summer.

We can build 30-story equivalent of chinese greenhouse – with thermo-blinds on during night, passive heat storage etc. Compared to chinese greenhouse it would have much higher construction cost, worse but comparable running conditions (available light, consumed energy, maintenance).

Pretty much every vertical farm concept includes electric grow lights. Conventional greenhouses get most of their light through the roof, but even they often use use supplemental electric light for winter production. If greenhouses are stacked, only the top story gets light through the roof. A little bit of light can penetrate the lower stories through the sides, but it is much less than most vegetable crops need to grow.

My wind cost estimate is based on actual wind turbines that have been in operation for the past decade. It’s possible that the cost of wind power will come down in the future. The Wikipedia article you referenced actually shows that costs have increased in recent years due to an insufficient supply of wind turbines. Regardless of cost considerations, I think that the tiny proportion of electricity that we generate from renewable resources can be put to better use than running electric grow lights in skyscrapers. Transitioning to a renewable energy economy demands conservation. Vertical farms demand more energy than conventional agriculture, not less.

Nice work.

Anyone with a rudimentary understanding of physics and energy can see that these drawings are little more than a techno-fantasy EROEI nightmare. I appreciate the work you’ve put into proving it.

It seems as though 1)we really don’t understand the true value of ecosystem services and 2) the urban bias of industrial economies is a legacy that will die hard as we transition into something more in balance with future energy limits.

Why as a culture are we so unwilling to move beyond solutions that try to outsmart nature? Will we keep fighting the current until we’ve exhausted ourselves and it takes us along?

This article seems to be struggling to point out negative aspects of vertical farming, instead of focusing on the real issues here. Traditional farming is no longer effective, especially in the coming years. Over the next 50 years the earths population will increase by 8.6 billion, requiring an additional 10^9 hecates of land. There simply wont be enough room to grow food. Traditional agriculture also consumes 70% of the worlds fresh water. Traditional agriculture also pollutes the environment heavily with fertilizers and pesticides in runoff water, not to mention the destruction of habitats. Farming is great, and its always been a necessity. However it can’t continue, it just won’t work.

I don’t buy your population projection. The UN’s low, medium and high range population projections for 2050 are 7.4, 8.9, and 10.6 billion, respectively (http://www.un.org/esa/population/publications/longrange2/WorldPop2300final.pdf). These represent respective increases of 0.5, 1.5, and 3.7 billion between now and 2050. In the longer term most projections see population stabilize or decline. No plausible scenario results in a population increase of 8.6 billion by 2061, which would bring world population to 15.5 billion.

The claim that feeding people will require another 10 billion hectares of farmland within the next 50 years would be implausible even if I accepted the alarmist population projection. At present some 1.5 billion hectares is used for arable and permanent crops (http://www.fao.org/docrep/004/y3557e/y3557e08.htm). You are suggesting that within 50 years we will need 6.7 times as much land as today to feed 2.2 times as many people.

Water is a renewable resource; fossil fuels are not. Land-based farming can pollute water, deplete aquifers, and alter the water cycle, but it can also be a sustainable part of a balanced water cycle. Water used by photosynthesis is released by respiration. Sustainable, rain-fed, land-based cropping systems can recycle water as well as vertical farms, without the huge energy input. We don’t need to farm in skyscrapers to avert agricultural water pollution.

This article discusses the energy implications of vertical farming, which I consider a deal-breaking negative. Working through the numbers was a little tedious, but not a struggle.

I agree, without moving to newer forms of farming (whether that be vertical, indoor or other) I suspect we, as a species will struggle to continue as is. I guess we can all start to talk about global warming being one of the main factors here, but we can never prove that all for sure.